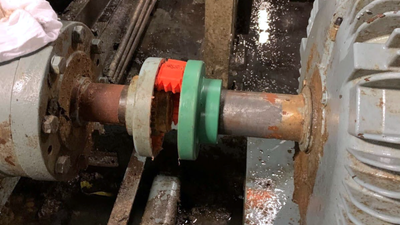

In the cement industry, where high-capacity, round-the-clock operations are the norm, certain machines do the heavy lifting day in and day out—ball mills, kiln drives, crushers, and fans. These workhorses of cement production are driven by high-torque connections between motors and gearboxes or between gearboxes themselves, often some of the machines operated via torsion shafts.

Yet, despite their critical role, these machines are overlooked during maintenance (due to their non-availability during production time)—especially when it comes to shaft alignment. The result? Higher power consumption, unplanned shutdowns, and accelerated equipment wear.

If your plant’s workhorses are out of alignment, your production—and profit margins—are likely taking a hit.

Why torsion shaft alignment matters in cement plants?

Torsion shafts are designed to transmit torque while absorbing misalignments and shocks between rotating components, specifically between mill and gearbox. But they aren’t a fix-all.

If alignment is poor, torsion shafts themselves become sources of mechanical stress, leading to a cascade of issues:

- Excessive vibration

- Coupling and bearing failures

- Gear wear

- Reduced energy efficiency

- Costly and frequent maintenance

- Risk of unplanned stoppages

Spotlight on the cement plant workhorses

Let’s break down how misalignment affects the cement plant’s most hardworking assets:

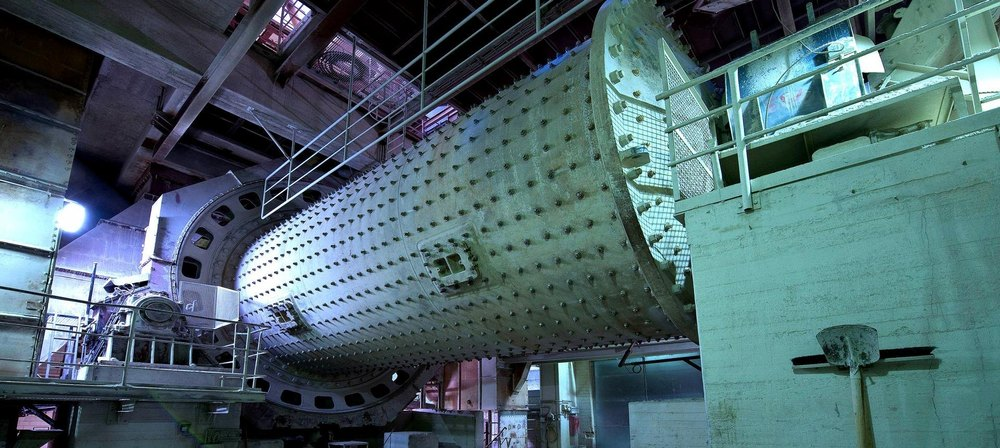

Ball Mills

Ball mills operate under immense load and torque, making alignment between the motor, gearbox, and mill essential.

Impact of misalignment:

- Uneven torque transfer

- Gearbox overheating

- Frequent coupling failures

A real case: A plant in Gujarat solved a persistent coupling issue in its ball mill by correcting a 3.5 mm/100 angular misalignment. The result? Vibration dropped by nearly 40%, and coupling life tripled—saving ₹18+ lakhs annually.

Kiln Drives

Rotary kilns run continuously and involve multi-stage gearboxes connected via torsion shafts.

Common issues:

- Shaft twisting due to thermal misalignment

- Coupling fatigue during startup/stop cycles

- Alignment shifts from base settling

Pro tip: Always factor in thermal growth during alignment—misjudging hot vs. Cold alignment can throw off precision significantly.

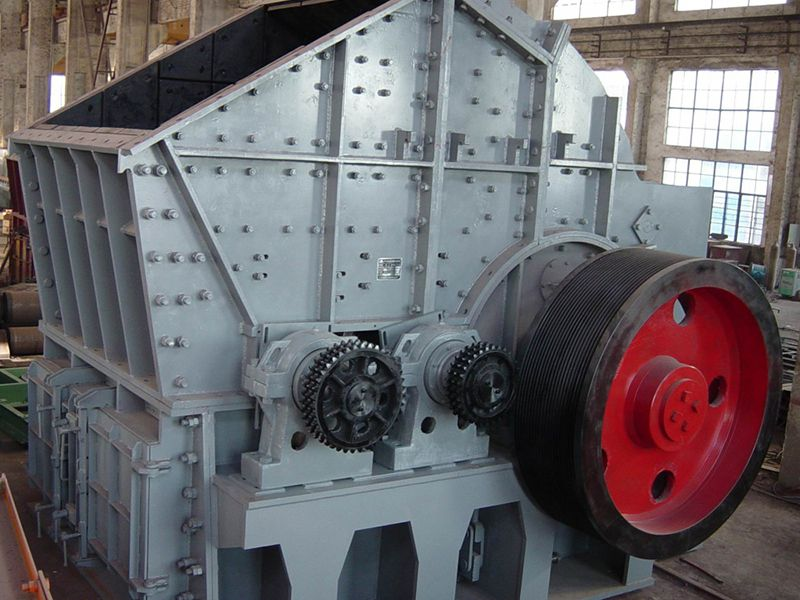

Crushers

Crushers endure shock loads and fluctuating torque, often leading to gearbox-to-gearbox misalignment.

Consequences:

- Torsional vibration

- Motor overload

- Frequent bearing replacements

In practice: A North India plant reduced vibration in its limestone crusher by correcting a 2 mm offset misalignment, increasing motor efficiency and cutting maintenance downtime in half.

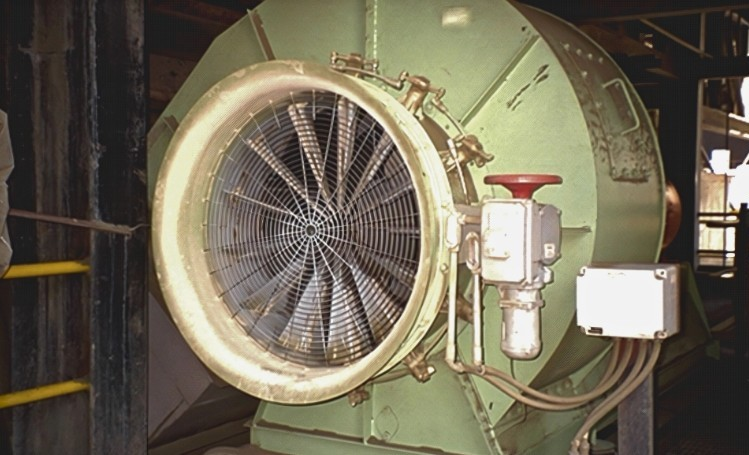

High-performance fans

Fans like ID, FD, and cooling fans maintain airflow across the plant. These units often run 24/7, transmitting torque through aligned drives.

What misalignment causes:

- High current draw

- Shaft deflection

- Structural resonance

Energy saving: After aligning a clinker cooler fan, one plant observed a 6% reduction in power consumption, saving ₹6–7 lakhs/year.

The real cost of misalignment

Think misalignment is minor? Think again. Across these machines, misalignment can lead to:

- Production loss per day: ₹8–15 lakhs (depending on equipment type)

- Energy loss: 5–10% more power drawn by misaligned equipment

- Component life reduction: Up to 70% in couplings and bearings

- Unplanned maintenance: Triggered by sudden failures

How to keep cement workhorses running strong

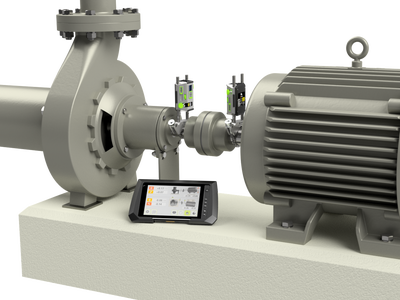

- Use laser shaft alignment tools

– Fast, accurate, and reliable under harsh plant conditions. - Schedule alignment checks during shutdowns

– Regular audits prevent long-term damage. - Train your teams

– Empower internal teams to catch misalignment early and accurately.

Alignment isn’t a one-time fix. it’s a maintenance mindset

Precision shaft alignment isn’t just a mechanical task—it’s an operational strategy. When your cement plant’s workhorses are in sync, they deliver more uptime, better efficiency, and longer service life.

And when they’re not? It’s a silent leak on your plant’s performance—and your bottom line.

How Acoem can help

At Acoem, we understand the rugged demands of cement manufacturing. Our wireless laser alignment systems, intuitive interfaces, and AI-powered diagnostic tools are purpose-built for industrial settings.

With Acoem, you are not just buying a package of monitoring instruments, you are investing in a holistic solution for asset reliability — an entire ecosystem that includes hardware, software, analytical platforms, maintenance and technical support, coupled with extensive expertise from a global team of maintenance specialists.